TAT Turbochrome offers a full range of repair and overhaul capabilities using special processes developed and/or implemented at our facilitiy to solve unique and complex problems.

Our modern, 60,000 sqft facility supports major airlines and engine shops around the world.

- Full in-house capability as a One Stop Shop

- Reliable supplier, offering short Turn Around Time

- Responsive Partner

- Broad scope of repair capabilities

- Innovative repairs and repair processes

Aircraft operators and engine shops looking for greater flexibility will find it at Turbochrome. The parts that we serve – We serve with attention, respect, and the highest level of quality. We will also find solutions for nonstandard repairs, drawing on decades of engineering knowledge.

Our Capabilities:

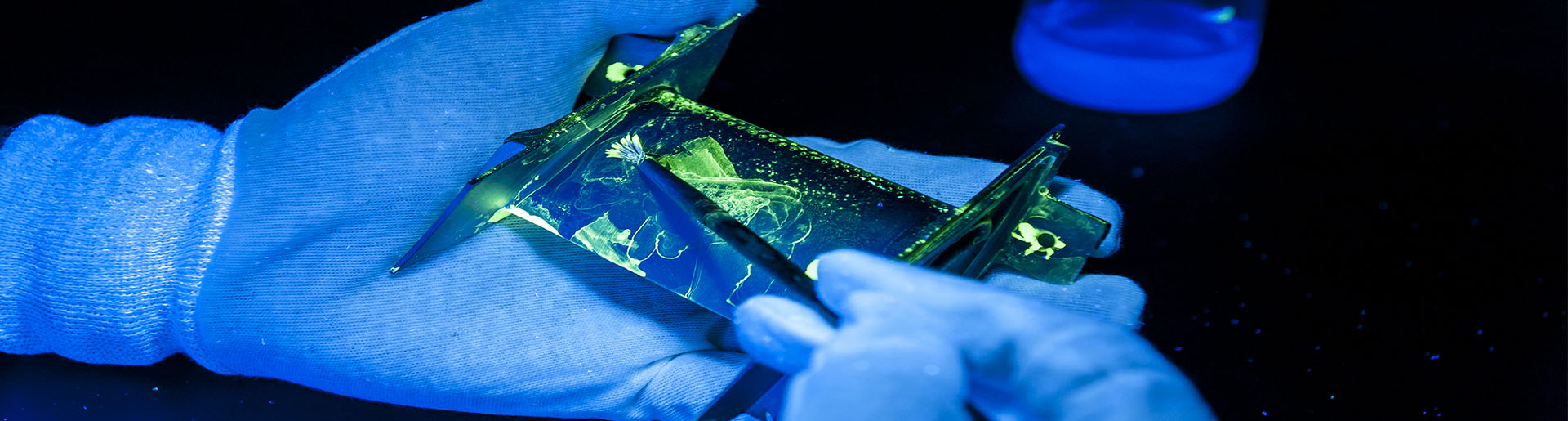

- NDT: X-Ray; FPI; Ultrasonic; Eddy Current and XRF

- Metallographic and Chemical Analysis

- Dimensional Inspection (3-axis computerized CMM)

- Vacuum Brazing and Heat Treatments in Argon and Hydrogen

- Plasma and HVOF coatings

- Electro-less coating of Nickel-Boron Thallium

- CBN Coating

- Diffusion coating (resist high temperature corrosion and erosion)

- EB Weld and TIG welding

- Electro-Discharge Machining (EDM)

- CNC Machining and Grinding

- Steel & Ceramic Shot Peening

- Surface Polishing

- Chemical Cleaning and Etching of Titanium Parts

CERTIFICATION

TAT Turbochrome was awarded the AS9100 Rev. D Certifications as well as Self-Release Supplier Status by the Israeli Air Force. In addition TAT Turbochrome holds FAA and EASA Certification.

At the start of 2018 TAT Turbochrome successfully passed the NADCAP audits and at present holds NADCAP accreditation for:

- NDT

- Welding

- Coatings

- Heat Treatments